© с сайта ТГУ

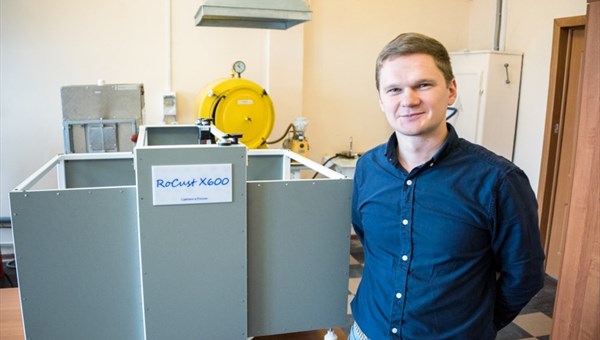

TOMSK, Oct 18 – RIA Tomsk. Scientists of Tomsk State University (TSU) together with engineers of the Tomsk company "InTeсh-M" collected a trial sample of the

Russia's first 3D-printer for monolithic ceramics printing, the press service

of the university reported on Tuesday.

Earlier it was reported that in TSU developed the 3D-printer which

doesn't have analogs and allowing to print from the ceramics, competing on the

properties with the high-alloyed steels, non-ferrous metals and solid alloys.

Advantage of ceramic materials – is in their high durability, hardness and so

on. Traditionally they are made by die casting method which doesn't allow to do

details of irregular shape.

"Now we can make elements of ceramics quicker, cheaper and more

precisely, than the casting method under pressure allows. Besides, we develop

methods of the press of products with small diameter of openings and thickness

of walls, demanded in microelectronics, – in general it's can't be received by

the existing methods", – the senior research associate of TSU Vladimir

Promakhov quoted in the message.

© сайт Томского государственного университета

It is specified that now scientists work on start of 3D-printers in

production, the first order from one of the leading Russian developers for the

press of elements of gas-turbine helicopter engines is also already received.

Thanks to the ceramics developed in TSU, these elements will be capable to maintain

vibration loadings at high temperature.

According to higher education institution, using of technologies of the

Tomsk scientists will allow to make unique products from ceramics of any,

superirregular shape with the set properties without costs of technological

preparation. "It will allow to reduce the price of the final product three

times, to accelerate and simplify input in production of new types of

production", – is said in the message.

Development of 3D-printing technology from ceramics is conducted with

assistance of a grant of the Russian Federal Property Fund and the

"Start" program of Fund of assistance to innovations. According to

the "Start" program scientists have to launch customized production

(under the specific consumer) on the basis of the Tomsk innovative enterprise

"Intekh-M" within three years.