TOMSK, Feb 9 – RIA Tomsk. Testing of scaffolds developed at

Tomsk Polytechnic University began (TPU) in St. Petersburg, in R. Gorbacheva Memorial

Research Institute of Children's Oncology, Hematology and Transplantation.

Scaffold – is a metal frame placed in a bone defect. Experts check whether it

will "germinate" by living cells, whether it will become a part of

the body.

Bacteriological tests performed earlier in Slovenia proved the antibacterial

effect of coatings of Tomsk scaffolds, brought scientists one step closer to

the creation of an implant "from an old age".

Why scaffolds are needed

The life expectancy of people is increasing, and one of the weak points at the

elderly person – is the bones. Therefore, the search for new effective methods

and materials for the reconstruction of bone defects – is a popular topic in

biomedicine. It is clear that young people, because of injuries damaged the

bones also need this.

© с сайта Томского политехнического университета

Modern scientists are no longer working on "prostheses" that would

replace damaged areas, but over the regeneration of tissues and organs. The

body itself can restore bone tissue, but it needs to be helped in it: to put on

the damaged area such a scaffold (frame for a new tissue), which, firstly, will

not be torn away, secondly, it stimulates the process of bone formation.

"The organism is aggressive towards the implant: it perceives it as a

foreign body and tries to get rid of it", – the engineer of the Laboratory

for Plasma Hybrid Systems of Nuclear Science & Engineering Laboratory TPU

Ekaterina Chudinova explains the main problem. Therefore, the structure and

coverage of scaffolds should be as close as possible to natural bone tissue – to be taken as "own".

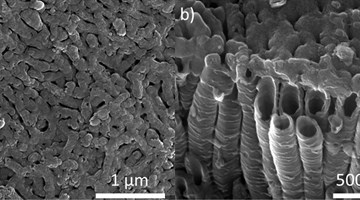

"Our scaffolds have a porous, reticular structure, due to this, living

cells can germinate into the material, which can not be achieved using

monolithic structures. Over time, cells "envelop" the entire

framework and it will become a part of the body. "Right now, the

specialists of the Research Institute of Children's Oncology, Hematology and

Transplantation named after Gorbacheva in St. Petersburg are exploring how

cells will grow when placed on our sample", – says Chudinova.

© Предоставлено Екатериной Чудиновой

Scaffold – is a mesh frame made of titanium alloy

What's inside

The scaffolds with which the engineers of laboratory work are made from an

alloy of titanium, aluminum and vanadium. Due to its strength, lightness,

biocompatibility, this alloy is widely used in biomedicine to replace

dysfunctional hard tissues. Frameworks are printed by polytechnicians on a

special 3D-machine at Mid Sweden University in Östersund, using one of the most

advanced methods of three-dimensional printing – electron beam melting.

"A layer of titanium alloy powder is applied, it is leveled with special

rakes, then an electron beam passes through to melt the powder. And in that

way layer by layer the given model reproduces. And this is the advantage

of additive technologies – it is possible to print everything you name it,

there would be a model!" – Ekaterina Chudinova explains.

Metal implants made in this way can in detail repeat the complex microstructure

of the bones.

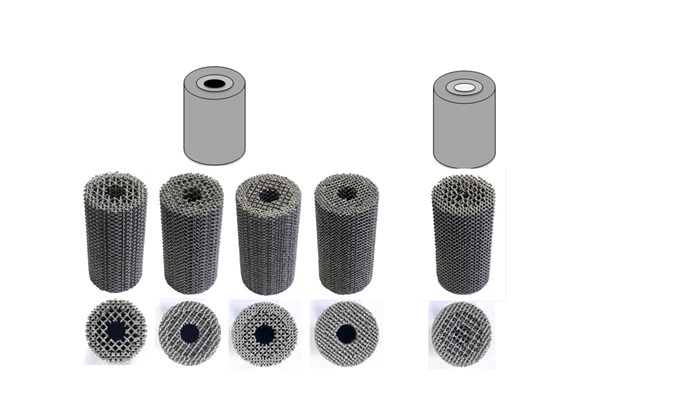

Chudinova also draws attention to the gradient structure of scaffolds – at the

edges it is created more dense than inside, because the main pressure falls on

the peripheral parts. Cavity inside is needed to place any substance which will

promote the further growth of tissue.

© предоставила Екатерина Чудинова

Ekaterina Chudinova specializing in physics (graduated last year), but she constantly comes into contact with chemistry and microbiology within the framework of the research.

What new polytechnicians invented

Swedish colleagues put implants in the form in which they now exist, – just

metal. Tomsk scientists of the Laboratory for Plasma Hybrid Systems are still

engaged in scientific research - they are looking for options of modification

of the surface of scaffolds. Catherine explains:

"Titanium belongs to the group of bioinert materials, and for improvement

of its biocompatibility it is better to apply coating. We proposed to spray

calcium-phosphate coatings on the surface of scaffolds and precipitate silver

nanoparticles. Calcium-phosphates are the main mineral constituent of bone (up

to 90% in composition), they belong to the group of natural metabolites, that

is, stimulate the processes of bone formation".

© с сайта ТПУ

Silver is known for its antibacterial effect.

"In 2017, I completed an internship at Jožef Stefan Institute where I was

engaged in microbiology. In particular, I conducted antibacterial tests – on

how the coatings will behave if they get bacteria. The tests confirmed that the

use of silver nanoparticles reduces the risks of infection during

surgery", – says Chudinova.

In parallel, Tomsk researchers are trying to improve the physical and

mechanical properties of scaffolds. When installing the implant, there is a

problem – a strong strain appears on the border with the bone, and with strong

mechanical stress the bone begins to break.

"It is necessary to maximally approximate the modulus of elasticity

of the implant to the modulus of bone elasticity. This is quite difficult – the

quantities are very different. Now we are trying to solve this problem by using

other alloys, in particular, low-modulus alloys with zirconium and niobium.

Very few people work with them – they rather expensive and are not easy to get.

But they have amazing properties!", – the scientist tells with

inspiration.

How is it assessed in the world

These experiments are closely monitored by colleagues from all over the world.

The last article about the manufacture of two- and three-layer scaffold mesh,

published in the journal Materials and Design (IF 4,364, Q1) by the employees

of the School of Nuclear Science & Engineering (by Maria Surmeneva, Roman

Surmenev, Ekaterina Chudinova, Mikhail Tkachev and Svetlana Gorodzha), became

the most media out of all scientific publications of TPU scientists in 2017.

It had the highest altimetric indicators, that is, the results of the work of

polytechnicians were most often mentioned and used on the Internet and traditional

media. Any achievement in the field of 3D-printing immediately becomes

noticeable in the world ...